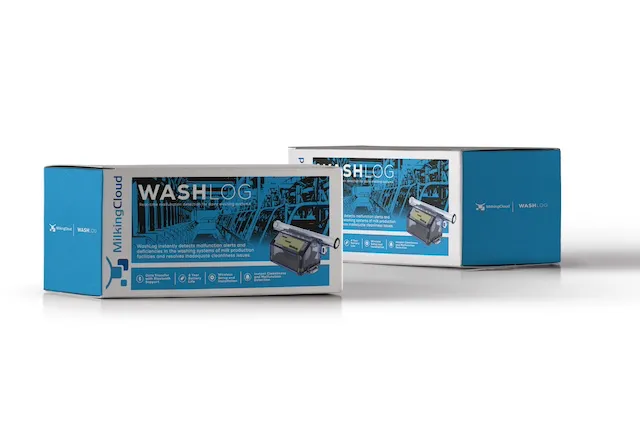

CIP (Clean-in-place) systems play a crucial role in maintaining hygiene and milk quality in the dairy industry. Ensuring these systems function efficiently is where WashLog steps in. This innovative device offers real-time monitoring and alerts to maintain optimal washing conditions, essential for preventing milk spoilage and equipment degradation.

WashLog provides a detailed log of each cleaning cycle, ensuring every phase meets the quality standards necessary for dairy production. It helps you avoid the risks associated with insufficient cleaning, such as bacterial growth and milk contamination, which can lead to significant financial losses and health risks.

Identify washing system faults and deficiencies in real-time.

Improve milk quality by addressing issues caused by thermophilic bacteria.

Can easily be installed by the user

Instant data exchange with Bluetooth supported data transfer

Operate it anywhere with its built-in battery.

Got Questions? Share your contact details, and let our experts provide the answers. We're just a call away!

Using WashLog leads to consistently safe milk production. Its precise monitoring ensures that all cleaning agents thoroughly sanitize the milking equipment, reducing the risk of contamination.

Prevent costly repairs and maintenance of milking equipment with WashLog. By ensuring proper cleaning, it extends the lifespan of your machinery, offering long-term financial benefits.

WashLog helps you adhere to strict dairy hygiene standards, making it easier to pass health inspections and maintain product quality, crucial for market competitiveness.

Leverage WashLog’s detailed cleaning logs to make informed decisions about your dairy cleaning protocols, optimizing both resources and time.

Faults and deficiencies in the washing system without real-time detection capability

A decrease in product quality due to inadequate cleaning

Inadequate and non effective cleaning of milking equipment.

Inability to access the necessary data for optimizing the milk production process.

WashLog should be installed in the last milking point on the milking line by cutting the silicone milk hose and inserting it in between. It does not require any electrical or data cable installation.

WashLog starts and goes to battery saver mode automatically

Monitors the quality and temperature of washing liquids after milking

If the washing level is not optimal, WashLog automatically alerts.

WashLog controls the washing processes of milking systems, monitors quality, and provides instant alerts in case of any issues. This allows you to maintain milk milking quality at the highest level.

WashLog detects contamination and faults that may occur in milking equipment and washing systems through high-precision sensors.

When a problem or cleaning issue is detected, the device immediately informs the user. This allows you to promptly address and resolve the problem.

It transfers collected data to devices quickly and securely via Bluetooth. This feature is highly convenient for data analysis and storage.

WashLog operates with an independent power source, which is a battery. This allows the device to be easily used anywhere and eliminates the dependence on an external power source.

Can easily be installed by the user. During the installation process, it is essential to install the device in a position in which sensors are facing the upwards.

Washlog, detect the milking and washing. When there is no activity, it switches itself to battery saving mode to save power.

The device creates detailed data logs for the washing process. These logs include specific information such as the temperature of the washing fluid, and the amount of acid and alkali, in addition to the overall condition of the milking system.

→ Prevents Milk Contamination

Regular use of WashLog removes bacteria, preventing milk contamination and spoilage.

→ Ensures Consistent Product Quality

Maintains high milk flavor and quality by consistent cleaning cycles.

→ Extends Equipment Lifespan

Reduces wear and tear, extending the operational lifespan of milking equipment.

→ Reduces Downtime

Efficient cleaning leads to fewer equipment breakdowns and less downtime.

→ Lowers Operational Costs

Proper maintenance reduces the frequency and cost of equipment replacement.

→ Enhances Milk Safety

Ensures milk safety for consumers by minimizing pathogen risks.

→ Supports Regulatory Compliance

Helps adhere to dairy industry hygiene standards, crucial for passing inspections.

→ Improves Environmental Sustainability

Efficient use of chemicals and water contributes to sustainable farming practices.

Discover the future of dairy farm management with our integrated technology suite, featuring MastiPro, WashLog, M2Moo, and PartuSense. Each device is designed to bring precision, efficiency, and health monitoring to your operations, revolutionizing the way you care for your herd and optimize your dairy production.

Streamline your operations with the MilkingCloud herd management software. MilkingCloud gets to know your farm through your data, provides customized alerts and recommendations tailored to your business. It assists you like a smart assistant.

"I've used the MilkingCloud app on my small farm in Pijao, Quindío, Colombia, and it's been a game-changer. The calendar and health modules streamline daily tasks and vaccination tracking. The ration module helps me calculate the best feed for my cows, optimizing costs. If it's this helpful for a small farm, I can only imagine its benefits for larger ones. Highly recommended for comprehensive farm management"

Cesar F.

Pijao, Quindío, Colombia

"I have been using MilkingCloud for over 2 years now and am very happy with it. We easily monitor every animal, and apply bulk operations, get reports that we generate, and must say we are happy with it."

Matthew P.

British Columbia, CA

He says he has started using the app recently and is still getting used to some of its uses. What he likes most about the app is that it helps him follow up on tasks like dry-off and vaccination. It is an intuitive and easy-to-use application.

Victor U.

Chile

MilkingCloud is being used over 600+ companies & dairy farms